Solving Digital Marketing Challenges for Businesses in Silicon Valley and Beyond

Ready to Grow Your Business?

Our Internet Marketing Process is All About You!

We take the time to understand your organization and customers, and then build a digital marketing strategy that is aligned and capable of delivering remarkable results. When you invest in any of WSI’s digital marketing solutions, you’ll have some of the top minds in the industry working on your vision.

Acquire More Leads and Sales

Generate quality leads through your website that are more likely to become your customers.

Grow Your Online Reputation

Turn your customers into your brand loyalists and biggest fans using Social Media the RIGHT way.

Build Brand Awareness

Get found by your customers and build more awareness about your services.

Improve an Ineffective Website

Transform your website into a lead generation machine for your business.

Our Digital Marketing Experience Runs Deep –

Across Most Industries You Can Think Of!

-

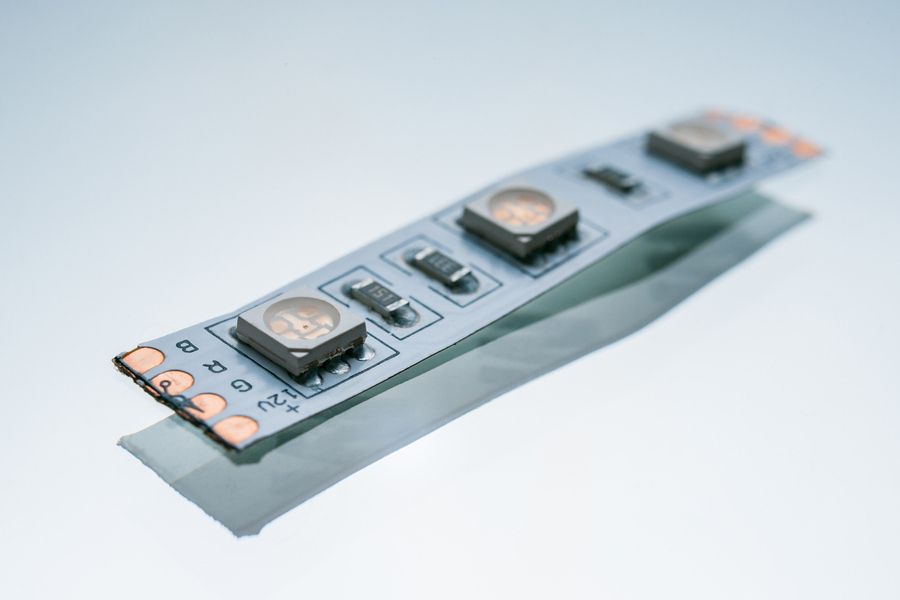

Increased Site Traffic Naturally by 75% In One Year

Our client, a small Silicon Valley electronic manufacturing company (EMS) had financing and a talented team of engineers were seeking to grow into their own facility rather than engineering solutions but outsourcing them to local companies.We met them at this early stage of their growth, and after review of their website and initial digital marketing efforts, suggested starting small as their marketing budget was also small. -

Increased Google Visibility by 92% in One Year

Our client, a California-based environmental engineering firm, had planned on starting a content marketing program internally but never got it off the ground. Their unique analytical and pollution remediation services are needed around the globe but their website had too little content and not enough focus.

-

Generated Over 136 Million Brand Impressions

Sunsweet is a brand recognized around the globe, yet they were struggling with brand consistency across their European markets. Partnering with WSI enabled them to skillfully overhaul their digital presence, bring unity across their website and social media campaigns, and exponentially increase their brand reach and generate conversion rates well beyond industry benchmarks. In fact, WSI’s work with Sunsweet earned them a WMA WebAward for the Food Industry Standard of Excellence category.In less than 4 minutes, watch what we did for Sunsweet and how we could do the same for you.

Best Digital Marketing Practices and Ideas

Wow, You Made it This Far!

Maybe you like what you see? Maybe you want to learn more. Give us a call for more actionable insights from our San Jose digital marketing experts – (510) 687-9737.